Industries that convert raw materials into homogeneous products typically use standardized processes to achieve uniformity in their end products. Homogeneous products, characterized by consistent properties and compositions, are prevalent in various industries, from manufacturing to food processing. This article explores the industries that engage in this type of production, the processes involved, and the benefits and challenges associated with it.

The conversion of raw materials into homogeneous products involves several key steps, including purification, blending, and standardization. These processes ensure that the resulting products meet specific quality and performance standards. Industries such as the chemical, pharmaceutical, and food industries heavily rely on these techniques to produce consistent and reliable products.

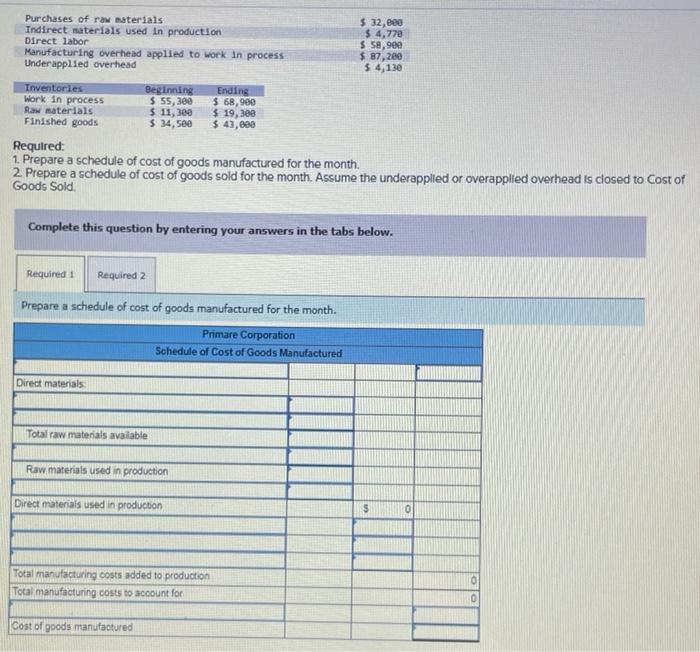

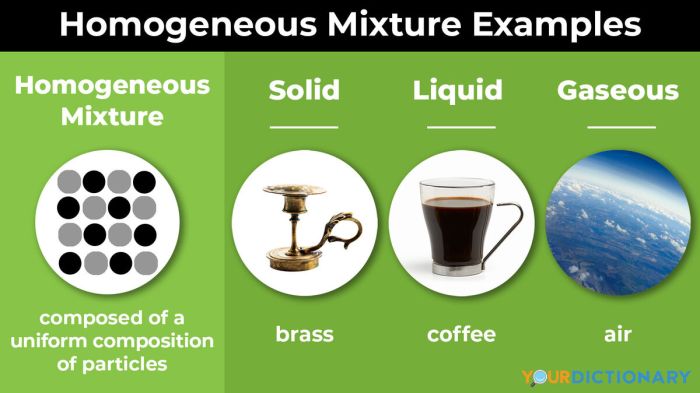

Definition of Homogeneous Products

Homogeneous products are goods that are identical in quality, form, and function, regardless of their source or producer. They are interchangeable and indistinguishable from one another, meaning that consumers perceive no significant difference between them.

Examples of homogeneous products include commodities such as wheat, gold, and oil, as well as manufactured products like steel, paper, and cement.

The defining characteristics of homogeneous products are:

- Uniform quality:They meet consistent standards and specifications.

- Lack of differentiation:Consumers cannot differentiate between products from different producers.

- Interchangeability:One unit can be easily substituted for another without affecting performance or satisfaction.

Homogeneous products differ from heterogeneous products, which exhibit significant variations in quality, form, or function. Heterogeneous products are often differentiated by brand, design, or other unique features.

Industries that Convert Raw Materials into Homogeneous Products

Primary industries that convert raw materials into homogeneous products include:

- Agriculture:Converts crops and livestock into commodities like wheat, corn, and meat.

- Mining:Extracts minerals and ores to produce homogeneous materials like steel, copper, and gold.

- Manufacturing:Uses raw materials to create standardized products like paper, cement, and textiles.

- Petrochemicals:Processes crude oil and natural gas into plastics, fuels, and other homogeneous products.

- Pharmaceuticals:Synthesizes active ingredients from raw materials to produce standardized drugs.

The processes involved in converting raw materials into homogeneous products vary depending on the industry and the specific raw material. However, common steps include:

- Extraction:Raw materials are extracted from the earth or harvested from crops.

- Purification:Impurities and unwanted elements are removed to achieve desired quality.

- Standardization:Raw materials are processed to meet consistent specifications.

- Forming:Products are shaped or molded into their final form.

- Packaging:Homogeneous products are packaged for storage and distribution.

Examples of Raw Materials and Homogeneous Products

| Raw Material | Industry | Process | Homogeneous Product |

|---|---|---|---|

| Wheat | Agriculture | Harvesting, milling | Flour |

| Iron ore | Mining | Extraction, smelting | Steel |

| Crude oil | Petrochemicals | Refining, distillation | Gasoline |

| Wood pulp | Manufacturing | Pulping, papermaking | Paper |

| Active pharmaceutical ingredients | Pharmaceuticals | Synthesis, purification | Drugs |

Challenges and Benefits of Converting Raw Materials into Homogeneous Products

Challenges:

- Quality control:Ensuring consistent quality and meeting industry standards.

- Process optimization:Streamlining processes to achieve efficiency and reduce costs.

- Environmental regulations:Complying with environmental laws and minimizing waste.

Benefits:

- Increased efficiency:Standardized processes and interchangeable products improve production efficiency.

- Cost reduction:Bulk production and economies of scale reduce production costs.

- Improved quality:Consistent quality control ensures high-quality products.

- Simplified distribution:Homogeneous products can be easily transported and distributed.

Technological Advancements in Homogeneous Product Production

Technological advancements have played a significant role in improving the efficiency and quality of homogeneous product production. Some key advancements include:

- Automation:Automated processes reduce labor costs and improve consistency.

- Computer-aided design (CAD):CAD software optimizes product design and manufacturing processes.

- Advanced sensors:Sensors monitor production processes and ensure quality control.

- Artificial intelligence (AI):AI algorithms analyze data and improve process efficiency.

These advancements have led to increased productivity, reduced costs, and improved product quality in homogeneous product industries.

Detailed FAQs: Industries That Convert Raw Materials Into Homogeneous Products Typically Use

What are the advantages of producing homogeneous products?

Homogeneous products offer several advantages, including increased efficiency in production, reduced costs due to standardized processes, and improved product quality and reliability.

What are some examples of industries that convert raw materials into homogeneous products?

Industries that engage in this type of production include the chemical industry (e.g., producing plastics and fertilizers), the pharmaceutical industry (e.g., manufacturing drugs and vaccines), and the food industry (e.g., processing and packaging food products).

What are the challenges associated with converting raw materials into homogeneous products?

Challenges can include ensuring the consistent quality of raw materials, maintaining precise production parameters, and meeting regulatory standards for product safety and performance.