When installing bonded clamps to support metal tubing, meticulous preparation and execution are paramount. This comprehensive guide provides a roadmap for successful clamp installation, ensuring optimal performance and longevity. From surface preparation to adhesive selection and application, each step is meticulously Artikeld, empowering you with the knowledge and confidence to achieve secure and reliable metal tubing support.

Preparation

Preparing metal tubing for bonded clamp installation is crucial to ensure a strong and durable bond. The process involves essential tools, materials, and safety precautions to achieve optimal results.

Tools and Materials, When installing bonded clamps to support metal tubing

- Wire brush or abrasive pad

- Cleaning solvent (e.g., acetone or isopropyl alcohol)

- Safety glasses

- Gloves

- Measuring tape

- Torque wrench

Safety Precautions

Always wear safety glasses and gloves when handling chemicals and sharp tools. Ensure adequate ventilation in the work area to avoid inhaling harmful fumes.

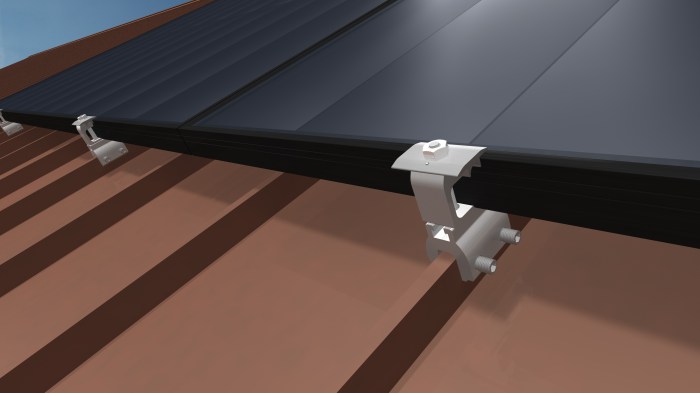

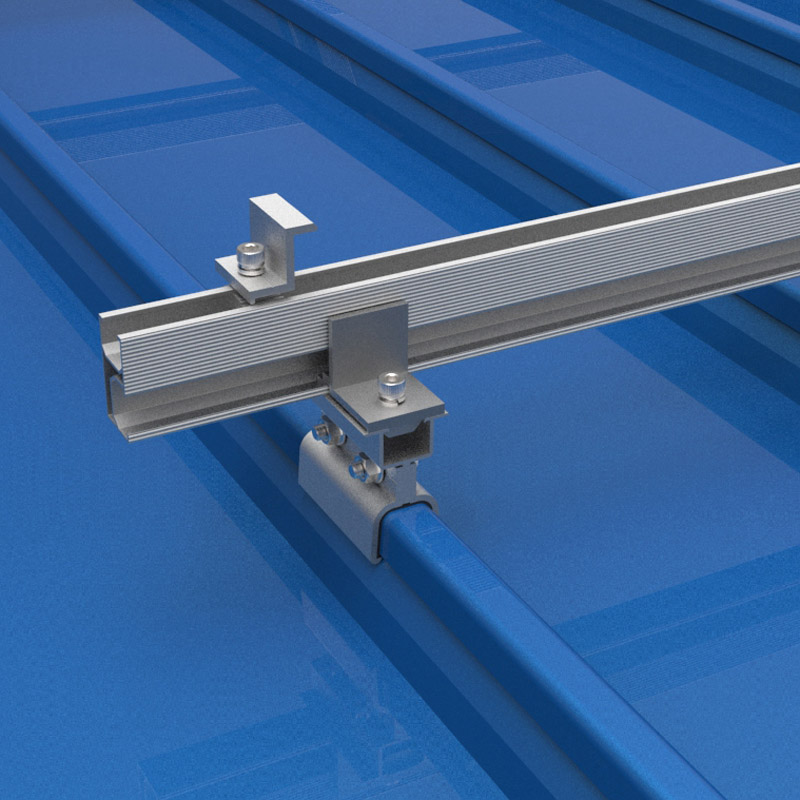

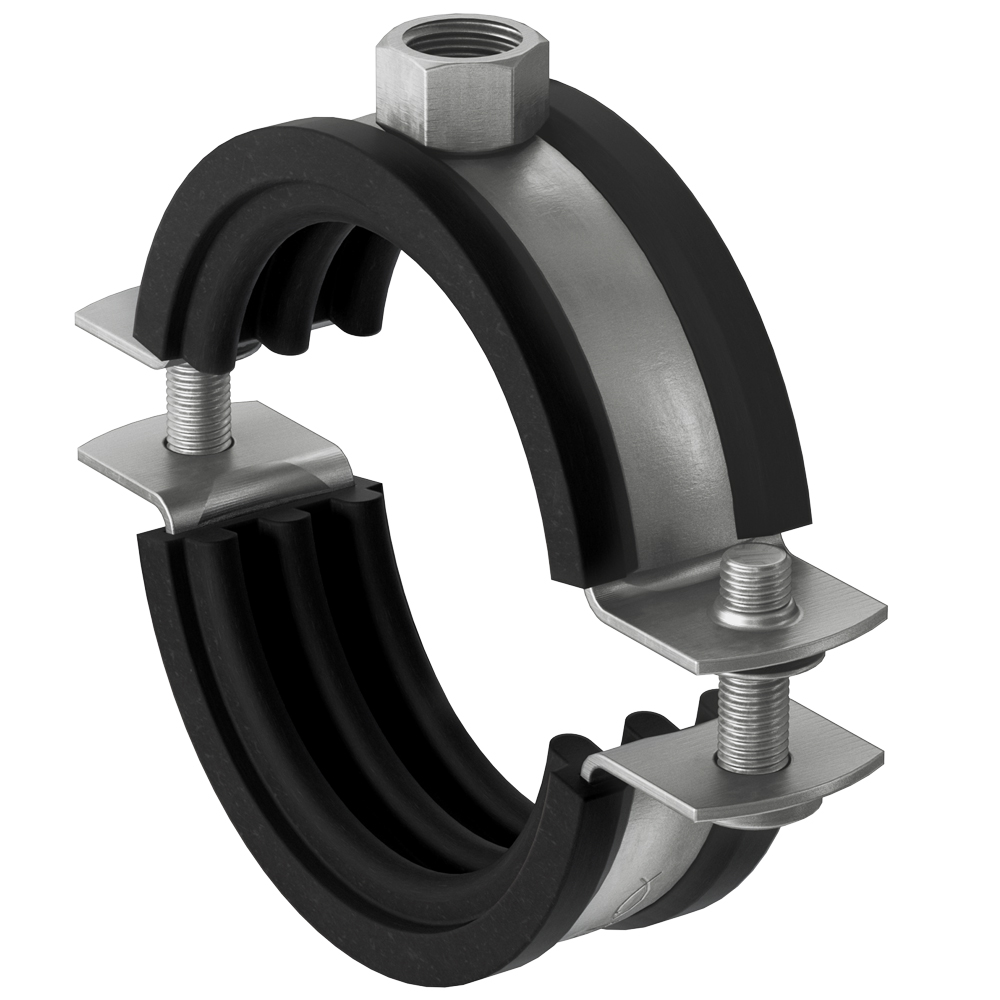

Clamp Selection

Bonded clamps come in various types, each suitable for specific metal tubing applications. Selecting the appropriate clamp is crucial for ensuring load capacity and longevity.

Clamp Types

- Single-bolt clamps:Suitable for low-pressure applications and small tubing diameters.

- Double-bolt clamps:Provide higher load capacity and are ideal for medium- to high-pressure applications.

- V-band clamps:Designed for high-pressure and high-temperature applications, providing a secure and leak-proof seal.

Clamp Size and Material

The clamp size should match the outer diameter of the tubing, while the material should be compatible with the tubing material and operating conditions. Common materials include stainless steel, aluminum, and galvanized steel.

Surface Preparation: When Installing Bonded Clamps To Support Metal Tubing

Proper surface preparation is essential for optimal bond strength between the clamp and the metal tubing. This involves removing dirt, oil, and other contaminants to create a clean and adhesive-ready surface.

Cleaning Process

- Thoroughly clean the tubing surface using a wire brush or abrasive pad to remove any rust, scale, or debris.

- Wipe down the surface with a clean cloth soaked in cleaning solvent to remove oil and grease.

- Allow the surface to dry completely before applying the adhesive.

FAQ Corner

What are the essential tools for installing bonded clamps?

Essential tools include a wire brush, cleaning solvents, torque wrench, and hex key.

How do I select the appropriate clamp size for my metal tubing?

Clamp size is determined by the tubing diameter and load requirements. Refer to the manufacturer’s specifications for guidance.

What type of adhesive should I use for bonding clamps to metal tubing?

Structural adhesives specifically designed for metal-to-metal bonding are recommended for optimal strength and durability.