Light duty tandem drive axles, the workhorses of the transportation industry, play a pivotal role in keeping our vehicles moving smoothly and efficiently. Dive into the world of these remarkable axles, where power meets precision, and discover their significance in various applications.

Their robust design and versatility make them indispensable components in a wide range of industries, from construction and agriculture to commercial transportation. Join us as we explore the intricate details of light duty tandem drive axles, uncovering their secrets and unraveling their impact on our daily lives.

Definition and Overview

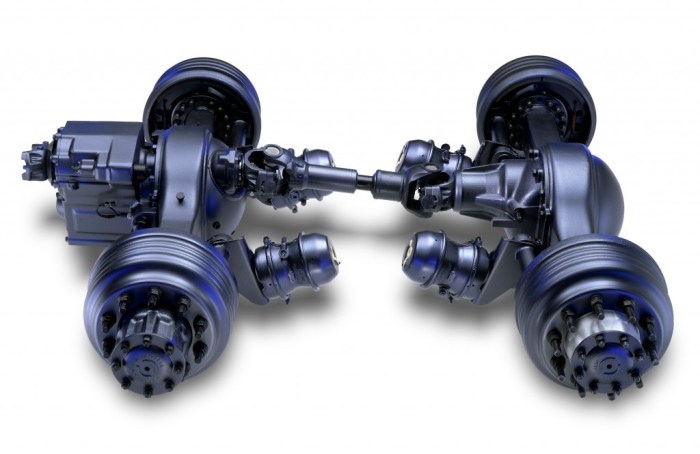

Light duty tandem drive axles, a fundamental component of various vehicles, are designed to enhance traction and load-carrying capabilities. They consist of two axles positioned one behind the other, both connected to the vehicle’s drivetrain. These axles work in conjunction to distribute the vehicle’s weight more evenly, providing greater stability and control.

Purpose and Function

The primary purpose of light duty tandem drive axles is to improve a vehicle’s performance in challenging driving conditions, such as uneven terrain, slippery surfaces, or when carrying heavy loads. By providing additional traction, these axles enable vehicles to maintain stability and maneuverability, even under adverse conditions.

Components and Design

Light duty tandem drive axles consist of various components, each serving a specific function in transmitting power and ensuring smooth operation.

These components are meticulously engineered using robust materials to withstand the demands of heavy-duty applications.

Key Components

- Axle Housing:The sturdy housing encloses and protects the internal components of the axle, safeguarding them from external elements.

- Differential:The differential allows the wheels on each side of the axle to rotate at different speeds, enabling the vehicle to navigate corners smoothly.

- Ring and Pinion Gears:These gears transmit power from the driveshaft to the differential, increasing torque and reducing speed.

- Axle Shafts:The axle shafts connect the differential to the wheels, transmitting power and supporting the vehicle’s weight.

- Wheel Bearings:These bearings support the axle shafts and allow the wheels to rotate smoothly, reducing friction and wear.

Materials and Significance, Light duty tandem drive axles

The materials used in the construction of light duty tandem drive axles play a crucial role in their performance and durability.

- Steel:High-strength steel is commonly employed for the axle housing and other load-bearing components, providing exceptional strength and resistance to deformation.

- Cast Iron:Cast iron is often used for the differential housing, offering a combination of strength, durability, and noise dampening.

- Alloy Steel:Alloy steels are utilized for axle shafts and gears, enhancing their toughness and resistance to wear and fatigue.

Types and Applications

Light duty tandem drive axles are commonly used in various industries and applications. They come in different types, each with unique characteristics and advantages, making them suitable for specific applications. Here are the most common types and their applications:

Single-reduction Tandem Drive Axles

- Provide a direct gear reduction from the transmission to the wheels.

- Suitable for applications where high torque and durability are required, such as dump trucks and construction equipment.

- Advantages: Simple design, cost-effective, and reliable.

- Disadvantages: Lower efficiency compared to other types, and may not be suitable for high-speed applications.

Double-reduction Tandem Drive Axles

- Utilize two sets of gears for reduction, providing higher torque multiplication.

- Commonly used in heavy-duty applications such as mining trucks and logging equipment.

- Advantages: Higher torque capacity, increased durability, and improved efficiency.

- Disadvantages: More complex design, higher cost, and increased maintenance requirements.

Planetary Tandem Drive Axles

- Employ a planetary gear set to achieve high torque multiplication and smooth power transfer.

- Suitable for applications requiring high torque and compactness, such as buses and motorhomes.

- Advantages: Compact design, high efficiency, and reduced noise levels.

- Disadvantages: More expensive than other types, and may require specialized maintenance.

Hub-reduction Tandem Drive Axles

- Integrate the gear reduction unit within the wheel hubs, providing increased ground clearance and reduced unsprung weight.

- Commonly used in military vehicles, off-road trucks, and heavy-duty construction equipment.

- Advantages: High ground clearance, improved off-road performance, and reduced maintenance.

- Disadvantages: More complex design, higher cost, and limited availability.

Performance and Maintenance

Light duty tandem drive axles deliver enhanced performance and durability, making them a reliable choice for various applications. They provide superior traction and stability, allowing vehicles to navigate challenging terrain and carry heavy loads effectively.

Maintaining these axles is crucial to ensure optimal performance and extend their lifespan. Regular inspections, lubrication, and adjustments are essential to keep the axles in good working condition. Additionally, adhering to manufacturer’s recommendations for maintenance intervals and using high-quality lubricants can significantly contribute to the longevity of the axles.

Maintenance Procedures

- Regular Inspections:Inspect the axles for any signs of wear, damage, or leaks. Check the axle housings, seals, bearings, and brake components for any abnormalities.

- Lubrication:Lubricate the axles according to the manufacturer’s specifications. Use high-quality lubricants designed for heavy-duty applications to reduce friction and protect the components from wear.

- Adjustments:Ensure proper alignment and adjustment of the axles. Misalignment can lead to premature wear and reduced performance.

Extending Lifespan

- Avoid Overloading:Exceeding the axles’ load capacity can put undue stress on the components, leading to premature failure.

- Proper Operation:Operate the vehicle within its intended design parameters. Avoid excessive acceleration, braking, or turning, as these can shock the axles and reduce their lifespan.

- Regular Maintenance:Adhere to the manufacturer’s recommended maintenance schedule. Regular inspections, lubrication, and adjustments can significantly extend the axles’ lifespan.

Market Trends and Advancements

The light duty tandem drive axle market is experiencing a surge in demand due to the increasing popularity of electric and hybrid vehicles, which require more efficient and reliable driveline systems. Additionally, the growing emphasis on fuel efficiency and emission reduction regulations is driving the adoption of lightweight and aerodynamic axle designs.

The latest advancements in the industry include the development of high-strength materials, innovative manufacturing techniques, and advanced electronic control systems. These advancements have led to lighter, more efficient, and more durable axles that can handle higher loads and provide improved performance.

Potential Growth Opportunities

- Increased demand for electric and hybrid vehicles

- Growing adoption of lightweight and aerodynamic axle designs

- Expansion of the automotive industry in emerging markets

Areas for Improvement

- Development of more efficient and durable axle designs

- Integration of advanced electronic control systems

- Reduction of production costs and lead times

Comparison with Other Axle Types: Light Duty Tandem Drive Axles

Light duty tandem drive axles offer unique advantages and considerations compared to other axle types. This section explores the similarities and differences between tandem drive axles and other axle configurations, highlighting their respective strengths and weaknesses in various applications.

Light duty tandem drive axles provide reliable performance for various applications. They offer improved traction and stability, making them suitable for a wide range of vehicles. Incidentally, laredo national bank v gordon is a notable case that dealt with issues of secured transactions and the rights of creditors.

Returning to our topic, light duty tandem drive axles continue to be a popular choice for enhancing vehicle capabilities in both on-road and off-road conditions.

Single Drive Axles

Single drive axles, as the name suggests, have a single differential and driveshaft connected to the transmission. They are typically used in lighter vehicles, such as pickup trucks and SUVs, where cost-effectiveness and fuel efficiency are primary concerns. Compared to tandem drive axles, single drive axles are lighter and less complex, resulting in lower production costs and improved fuel economy.

However, single drive axles have limited torque capacity and traction, making them less suitable for heavy-duty applications or vehicles that require enhanced traction in challenging conditions. In slippery or off-road environments, single drive axles may struggle to maintain traction, leading to reduced performance and potential safety concerns.

Tandem Drive Axles

Tandem drive axles, on the other hand, consist of two drive axles connected by a driveshaft. This configuration provides increased torque capacity and improved traction, making them ideal for heavy-duty vehicles, construction equipment, and off-road applications. By distributing the driving force across two axles, tandem drive axles can handle higher loads and provide better stability in adverse conditions.

However, tandem drive axles are heavier and more complex than single drive axles, which can impact fuel efficiency and increase production costs. Additionally, the increased number of components in tandem drive axles requires more maintenance and servicing, potentially increasing operating expenses over time.

All-Wheel Drive (AWD)

All-wheel drive (AWD) systems distribute power to all four wheels of a vehicle, providing enhanced traction and stability in various conditions. AWD systems typically employ a transfer case or differential to split the driving force between the front and rear axles, allowing for optimal power distribution and handling.

Compared to tandem drive axles, AWD systems offer improved traction and stability in slippery or off-road conditions. However, AWD systems are more complex and expensive to implement, and they may have a slight impact on fuel economy due to the additional powertrain components.

Conclusion

The choice between light duty tandem drive axles and other axle types depends on the specific application and performance requirements. Single drive axles are cost-effective and fuel-efficient for lighter vehicles, while tandem drive axles provide enhanced torque capacity and traction for heavy-duty applications.

AWD systems offer improved traction and stability in various conditions, but they are more complex and expensive to implement.

Case Studies and Applications

Light duty tandem drive axles find widespread applications in various industries. Here are a few real-world case studies that showcase their effectiveness:

One notable case study involves a construction company that utilized light duty tandem drive axles on its fleet of concrete mixer trucks. The axles provided enhanced traction and stability, allowing the trucks to navigate challenging construction sites with ease. The company reported a significant increase in productivity and reduced downtime due to fewer incidents of getting stuck or experiencing axle failures.

Challenges Faced and Solutions Implemented

In another instance, a transportation company encountered challenges with axle durability and maintenance costs on its light-duty delivery vehicles. The company implemented light duty tandem drive axles, which resulted in increased axle life and reduced maintenance expenses. The tandem axles better distributed the load, reducing stress on individual components and extending their lifespan.

Success Stories and Lessons Learned

A food and beverage distribution company successfully employed light duty tandem drive axles on its refrigerated delivery trucks. The axles improved vehicle stability and handling, particularly during turns and when carrying heavy loads. The company experienced fewer accidents and reduced product damage, leading to improved customer satisfaction and cost savings.

These case studies highlight the versatility and benefits of light duty tandem drive axles. They demonstrate how these axles can enhance vehicle performance, reliability, and safety in various applications.

Quick FAQs

What are the advantages of light duty tandem drive axles?

Increased load capacity, improved traction, enhanced stability, and reduced tire wear.

What are the different types of light duty tandem drive axles?

Single-reduction, double-reduction, and planetary axles.

How do I maintain light duty tandem drive axles?

Regular inspections, lubrication, and component replacements as needed.